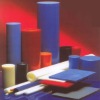

- Plastic Sheets[10]

- Plastic Rods[5]

- Contact Person : Mr. Lee Vincent

- Company Name : Shanghai Tianjin Plastics Co., Ltd.

- Tel : 86-769-23132166

- Fax : 86-769-23135866

- Address : Guangdong,Dongguan,Room 608, Zhonghuan Building, No.169, Bada Road,Guancheng District

- Country/Region : China

- Zip : 523011

white pom rods

Polyoxymethylene (POM )rods specification:

Sheet thickness:3mm~150mm; (W)1000mm*(L)2000mm; (W)6000mm*(L)1000mm; (W)1200mm*(L)1000mm ; (W)6000mm*(L)1200mm

Rod thickness:3mm~280mm; (W)1000mm*(L)2000mm; (W)6000mm*(L)1000mm; (W)1200mm*(L)1000mm ; (W)6000mm*(L)1200mm others can do as customer requirements

POM rods Features:

a general engineering thermoplastics with excellent mechanic properties,eletrical properties,wear resistanance,dimensional stability,chemical corroosion,in particular,are resistant to fatigue-type attack,and good self-lubricating,are latent behalf of the matal,especiallly coper and aluminnum, zinc and other non-ferrous metals and alloys ideal for engineering plastics manufacture.

POM rods Advantages:

1)No microporosity.

2)High strength

3)High rigidity

4)High thermal stability

5)Good electrical insulation properties

6)Very good sliding properties

7)High resistance to solvents

8)Very high resistance to stress cracks

POM rods Disadvantages:

POM by acid erosion, weathering poor, poor adhesion, thermal decomposition and softening nearly stable, so melting process more difficult. Limiting oxygen index for the smallest plastic, it is easier to burn.

POM rods Application:

Because POM has excellent chemical resistance and very low moisture absorption, it is often chosen and is a widely specified engineering plastic within the brewing industry. Also because of the very low moisture absorption, POM sheet is highly recommended within the food industry having received Food & Drug Administration approval and also the marine industry for the fact that POM sheet is non hydroscopic the finished machined product will not expand or swell due to moisture absorption.

POM rods Technical date reference :

Property | Test Method | Test date | Unit | |

Physical property | Density | ASTM D-792 | 1.41 | sp gr23/23°C |

Melt flow speed.

| ASTM D-1238 | 9 | g/10min | |

Mould shrink rate | ASTM D-955 | 0.02 | % | |

Mechanical properties

| Elongation at break | ASTM D-638 | 00 | ft-ibin |

Non-notched impact Strength | ASTM D-256 | n/a | Psi | |

Bending strength | ASTM D-790 | 13.000 | Psi | |

Flexural modulus | ASTM D-790 | 3.700 | Psi | |

Rockwellhardness | ASTM D-785 | 80 |

| |

Tensile strength | ASTM D-638 | 8.890 | ft-ibin | |

Notch impact strength | ASTM D-256 | 1.2 | ft-ibin | |

Electric property | Volume resistivity | ASTM D-257 | 1.00E+14 | Ohm-cm |

Dielectric constant | ASTM D-150 | 3.700 | ||

Surface resistivity | ASTM D-257 | 1.00E+16 | Ohm | |

Dissipation factor | ASTM D-150 | 0.007 | ||

Dielectric strength | ASTM D-149 | 483 | V/mil | |

Packaging & Delivery

Packaging Detail: Standard packings are wooden pallet and wooden case with PE firm packingDelivery Detail: 15-20days after advanced payment

white pom rods